Nation I Turn Window (Inward opening)

- Product information:

- Uw: 0,82 (Medi g) | 0,85 (High g)

- Glass dimensions: Triple glazing (48 mm): 4-18-4-18-4

- Styling bar: 22/23 mm og 42 mm

- Frame dimensions: 50 x 122 / 149 mm

Due to changed guidelines from Google Play, we have created an updated version of our installation app.

The existing app will soon become inactive. We kindly request all installers to download the new app and uninstall the old one.

Use:

The Turn window has the most stable locking and is without risk of incorrect operation. Turn windows can typically be recommended for large openings. Frame I / Nation I (inward opening) and Frame IC / Nation IC (outward opening) have the same outer sash-frame height and can therefore be placed in the same elevation, without there being much visual difference. The revolving window can also meet all the building regulations' requirements for egress openings.

Function:

Turn windows are inward opening windows with a side-hung function. The opening function is controlled by a lever handle operating an espagnolette in the side or bottom sash. In the closed position, the handle faces vertically downwards (or horizontally) and the turn function is triggered by turning the handle 90 °. The Turn window can, as an option, be supplied with a handle-operated brake. The brake can, in the side hung function, hold the frame in any position above 18 ° opening.

Correct installation and maintenance is important to ensure full warranty coverage.

To ensure that the windows and doors function and operate optimally, it is important that they are installed correctly. Incorrect installation may result in product failure which is not covered by the warranty.

If you have any questions regarding the installation of the elements, please call our Service Department on tel. 01582 860 940. They will be happy to help you.

When unloading and handling the elements, use tools and methods which do not cause damage the elements or the health of those on site.

Upon receipt, the purchaser must check that the consignment complies with the agreement and that the elements are free from apparent defects, faults or transportation damage. If there is any cause for complaint, please notify Idealcombi’s Service Department on tel. 01582 860 940 before installing the elements.

Stickers and cork chips on window glass should be removed 1-2 weeks after receipt. Corner protection, protective films and other packaging must only be removed before installing the elements.

If stored outdoors, the elements must be placed on battens or pallets to keep them clear of the ground. The elements must be covered with a suitable and secure material to protect them from precipitation and dirt. Allow for sufficient ventilation around the elements in order to reduce the risk of condensation forming underneath the covering and excessive heat building up due to direct sunlight. Individual window elements should be stored under a roof structure, in a container or preferably inside.

Our windows and doors are supplied with a small tin of paint in their particular colour. The paint is intended for repairing any minor damage caused during installation, but can also be used subsequently. Idealcombi’s Service

Department is always willing to offer help and advice on surface treatment maintenance and on where to buy additional paint in a particular colour for later use.

Correct installation is important for the function and life of the elements. The installation should therefore be carried out by professional fitters of windows and external doors.

The instructions in this manual cover some of the main issues – but not every detail – which may be relevant during installation.

Back boards on fully insulated spandrel panels are loosely fitted. After installation the cavity is insulated and a damp membrane fitted. Then the back board is sealed and fixed with nails.

The window is usually placed within the outer leaf construction of the wall. It should be fitted centrally giving uniform gaps between the frame and structure – ideally the gaps should be 10 to 15mm. The window should be installed with the frame plumb both

horizontally and vertically and should be adjusted and fixed to ensure the correct closing position between the frame and sash.

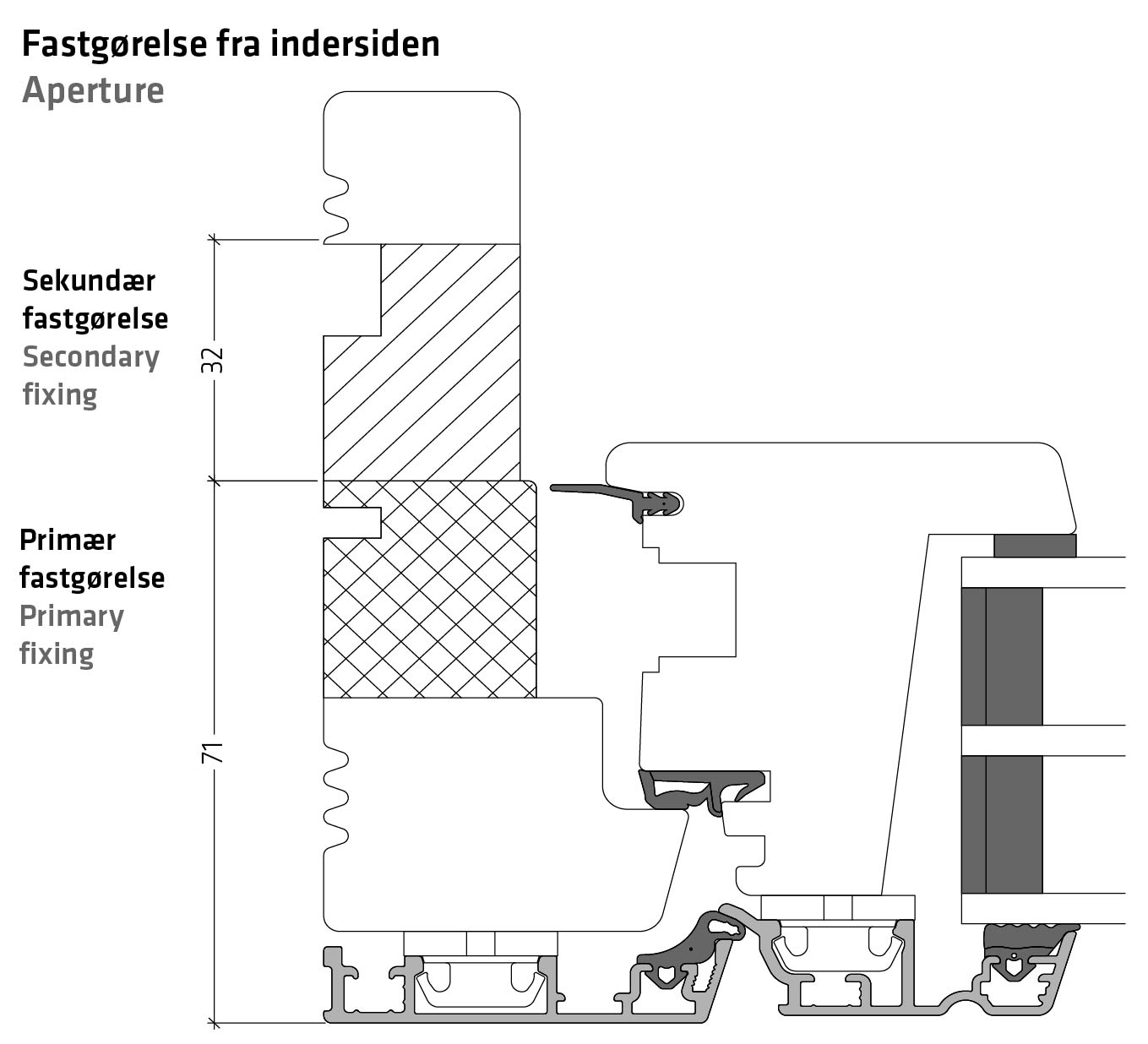

Securing, general

Windows and external doors should always be fixed to the building structure using mechanical fixings such as frame bolts / screws.

If any foaming material is used to fill the gap between the outer frame surface and the structure the element must be fixed first using mechanical fixings.

Sealant

The sealant work must be carried out in accordance with sealant manufacturers recommendations and current standards.

When filling gaps with insulation (expanding foam) never put in too much so that it bows the frame. After the expanding foam has cured a waterproof sealant should be applied to the outside (see paragraph on sealant types). To make sure you have enough depth

(in accordance with the sealant manufacturers recommendations) you may have to rake back the expanding foam insulation.

Sealant types

There are a wide range of sealing products to choose from for use between frames and outer walls.

The two most common types are:

– Plastic or elastic mastic

– Asphalt saturated plastic foam (Illmod sealing tapes)

Please refer to sealant manufacturers guide lines to ensure correct product and size before applying.

In order to preserve the wood and reduce heating consumption, it is important that the sealant stays intact. The sealant should therefore be inspected at least once a year, and any flaws should be remedied using the same type of sealant as the original. In case

of any major flaws, all the sealing material must be replaced. In such cases, it must be assessed whether a different type of sealant would be more suitable than the existing one.

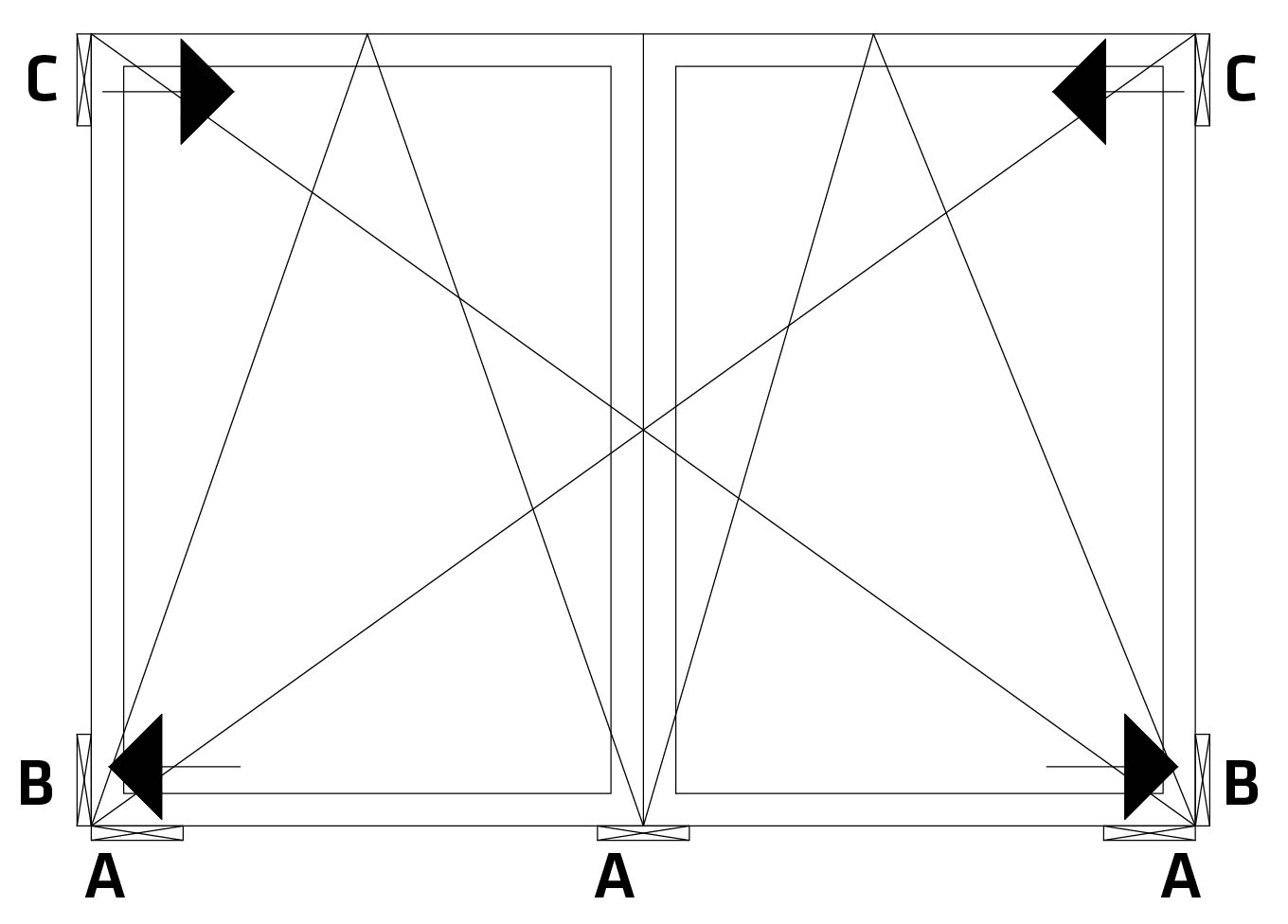

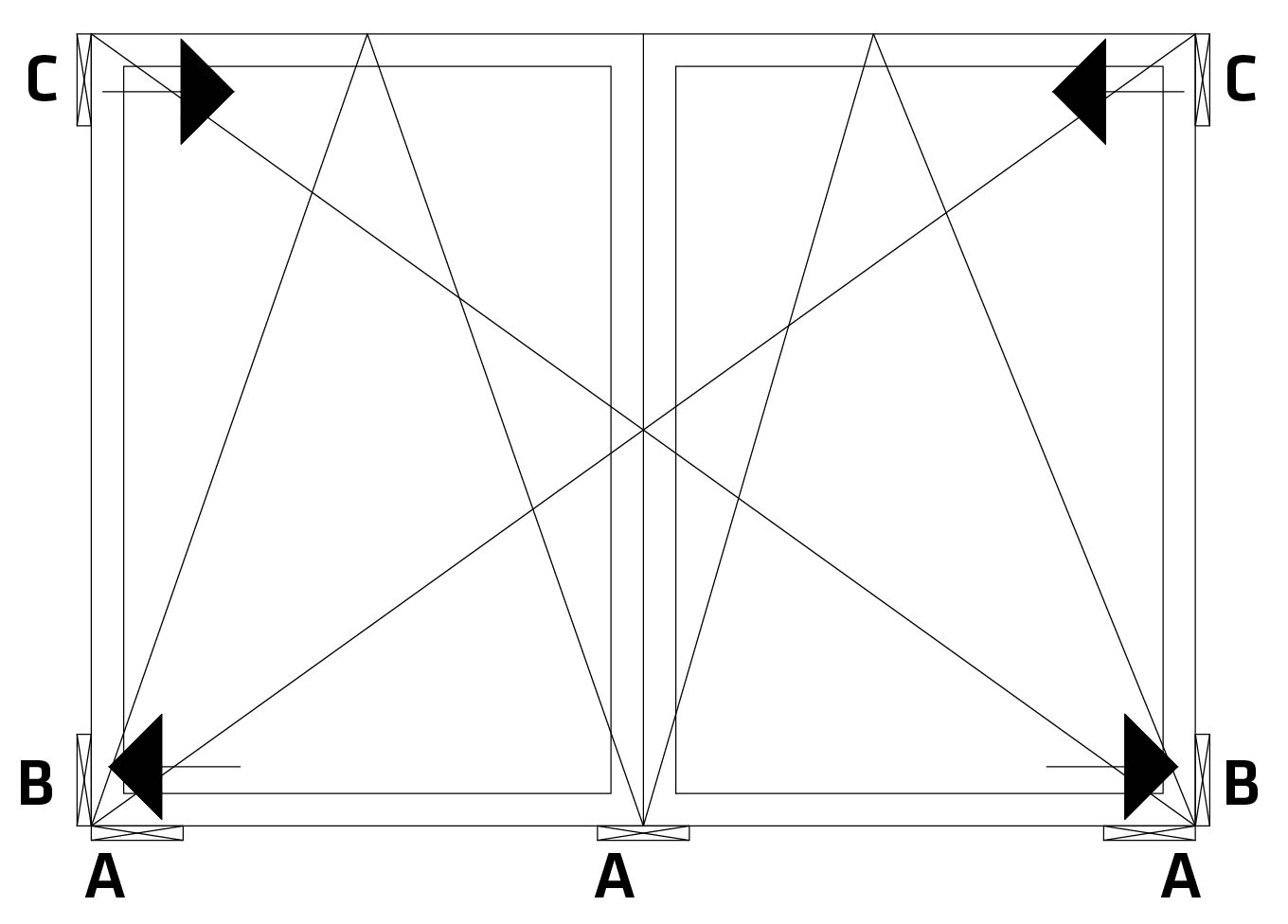

Place permanent wedging under jambs and any mullions to ensure that the weight of the window element is supported by the underlying structure (A)

For windows with floating mullions, place wedging under jambs and floating mullion to ensure that the weight of the unit is supported by the underlying structure (A)

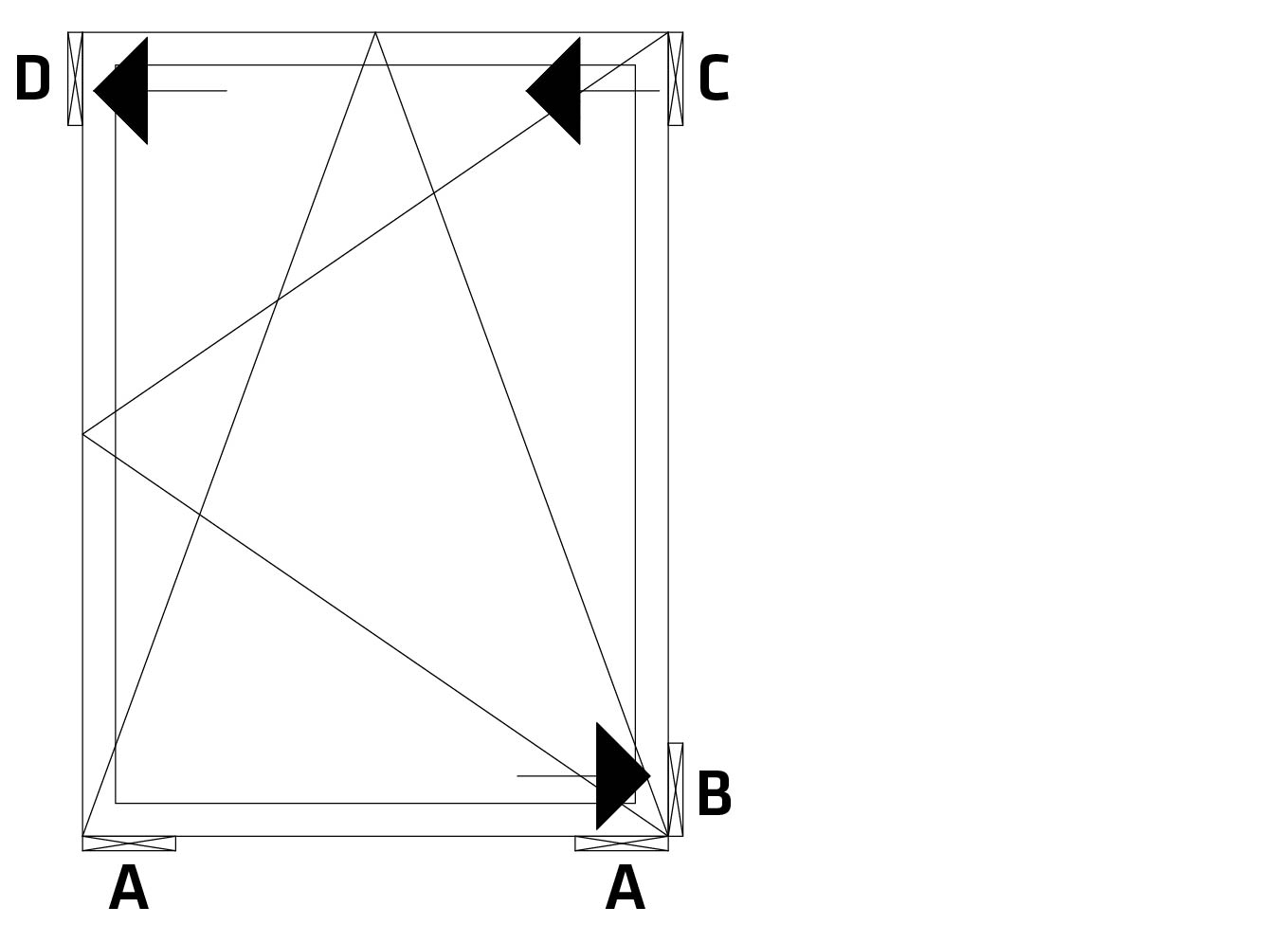

The sill must be horizontal and straight. It must under nu circumstances curve upwards or downwards. Place permanent wedging below the jamb at the hinge side of the unit (B). When securing, ensure that the point can absorb compressive forces.

Place permanent wedging at the top of the jamb on the hinge side of the unit (C). When securing, ensure that the point can absorb tensile forces.

Place permanent wedging above the jamb at the closing side of the unit (D); when securing, this wedging must ensure that the point can absorb compressive forces.

For a unit height of above 1600 mm, wedging on both sides at the top of the frame is required.

For increased security and strength a permanent packer can be placed behind ironmongery fix points and locking points.

Jambs should be perfectly plumb and square, and can under no circumstances bow.

During installation, the clearance, i.e. the space between the frame and sash, should be adjusted according to the function of the element. The closing side must be adjusted to provide a tight seal when closed.

The tolerance on diagonal measurements is ±2 mm.

Permanent wedging on the frame head may only be used if the load from any window/door elements above does not subject the unit to stress apart from at the jambs and mullions.

Permanent wedging must be moisture resistant min. 40 mm wide. Depending on the sealant location it is recommended to use anti-slip tape

Wedging material must be moisture resistant, min. 40 mm wide and be placed so that it at least supports the fitting groove.

Depending on the location of the seal, it is recommended that anti-slip tape is used on the wedging material according til the FSO Sealand Guidelines.

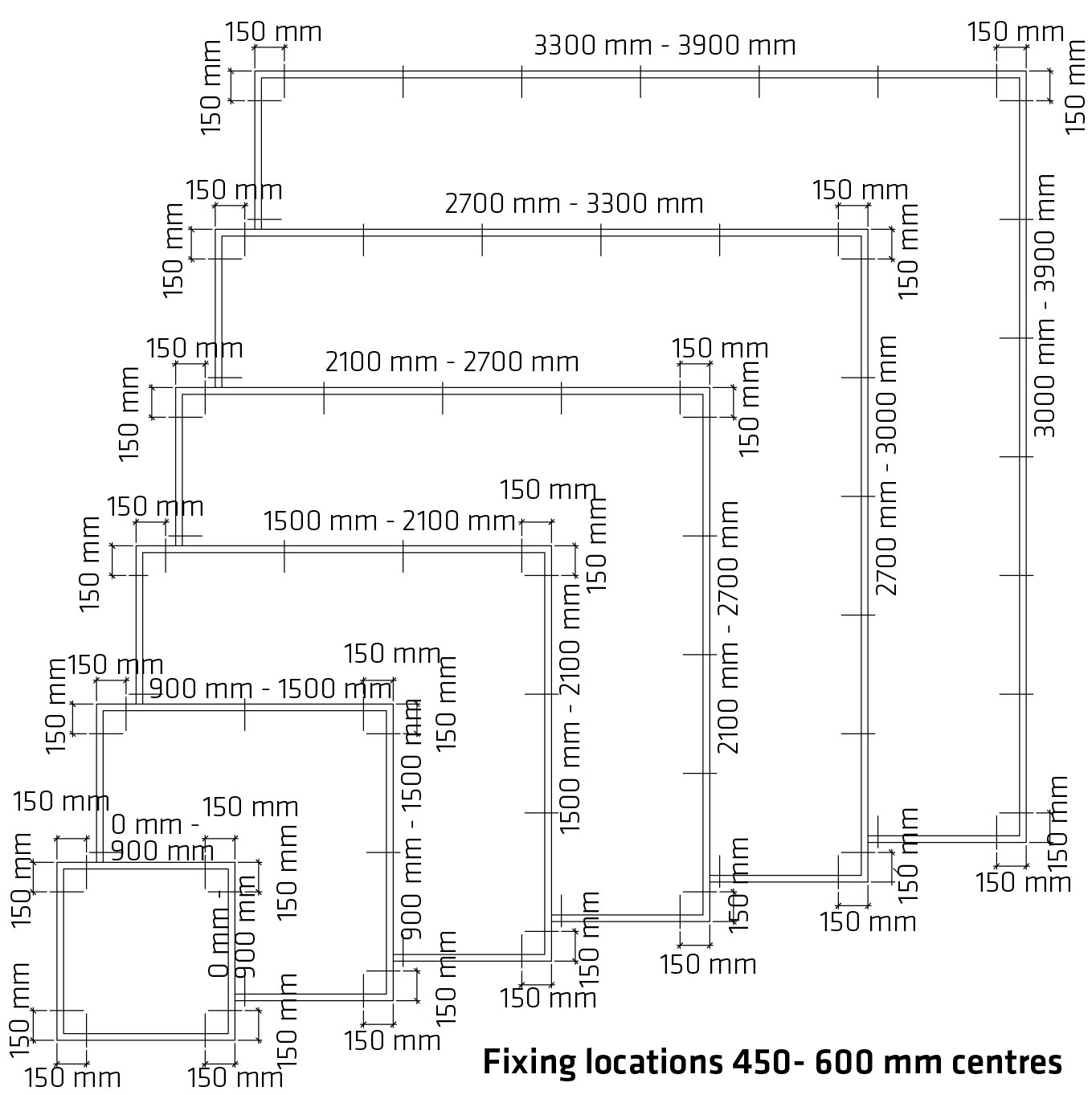

When fixing directly through the frame into the building structure locate the fixings in the shaded area shown below. Jambs should be fixed 150 mm from the corners and at a distance of no more than 600mm between fixings. At the head and cill the fixing points can be max 600 mm apart.

For element widths under 600 mm fixings in head and sill can be omitted.

It is recommended that headed screws are used when fixing and that the profile is countersunk for the screw head.

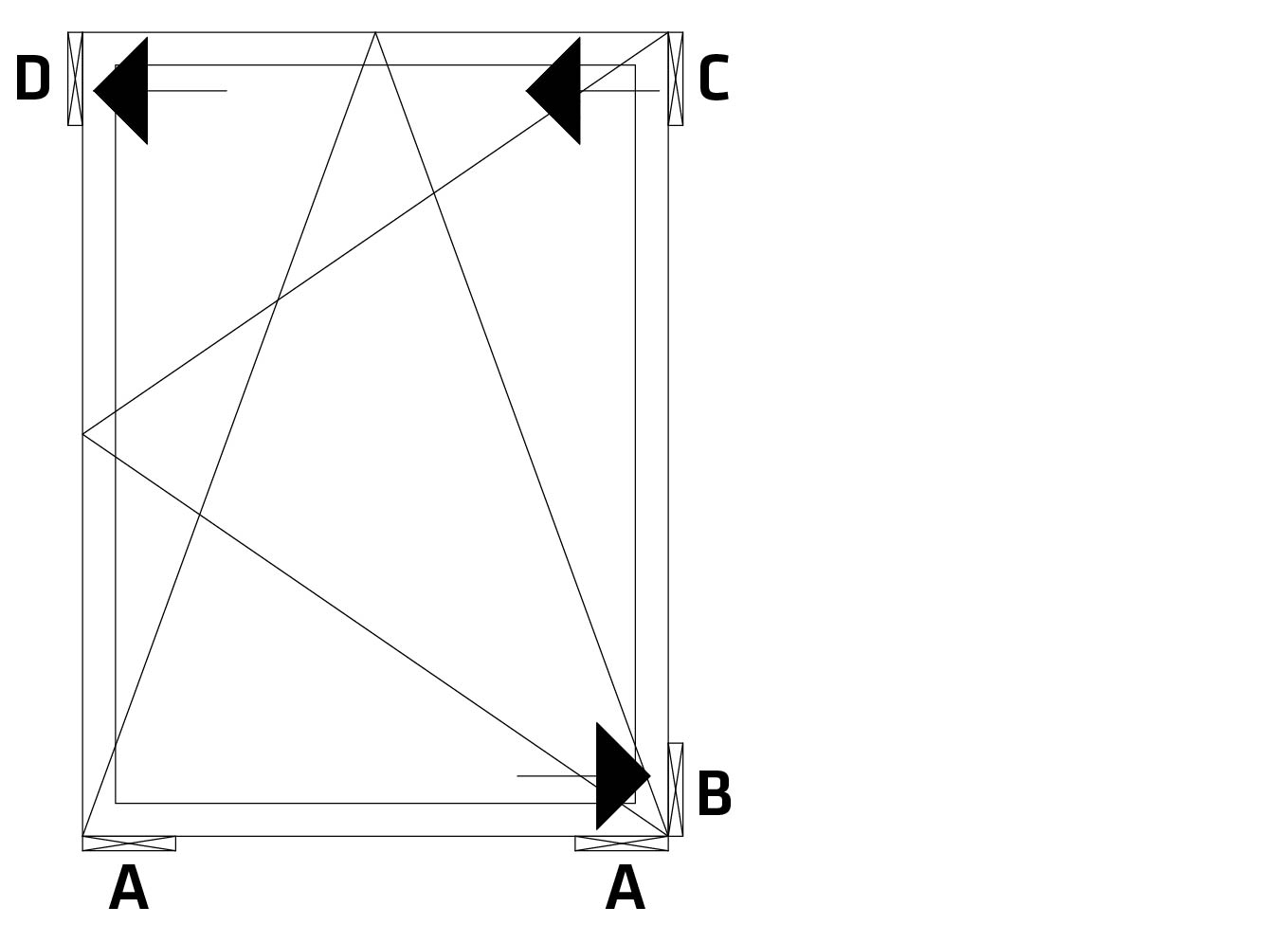

Place permanent wedging under jambs and any mullions to ensure that the weight of the window element is supported by the underlying structure (A)

For windows with floating mullions, place wedging under jambs and floating mullion to ensure that the weight of the unit is supported by the underlying structure (A)

The sill must be horizontal and straight. It must under nu circumstances curve upwards or downwards. Place permanent wedging below the jamb at the hinge side of the unit (B). When securing, ensure that the point can absorb compressive forces.

Place permanent wedging at the top of the jamb on the hinge side of the unit (C). When securing, ensure that the point can absorb tensile forces.

Place permanent wedging above the jamb at the closing side of the unit (D); when securing, this wedging must ensure that the point can absorb compressive forces.

For a unit height of above 1600 mm, wedging on both sides at the top of the frame is required.

For increased security and strength a permanent packer can be placed behind ironmongery fix points and locking points.

Jambs should be perfectly plumb and square, and can under no circumstances bow.

During installation, the clearance, i.e. the space between the frame and sash, should be adjusted according to the function of the element. The closing side must be adjusted to provide a tight seal when closed.

The tolerance on diagonal measurements is ±2 mm.

Permanent wedging on the frame head may only be used if the load from any window/door elements above does not subject the unit to stress apart from at the jambs and mullions.

Permanent wedging must be moisture resistant min. 40 mm wide. Depending on the sealant location it is recommended to use anti-slip tape

Wedging material must be moisture resistant, min. 40 mm wide and be placed so that it at least supports the fitting groove.

Depending on the location of the seal, it is recommended that anti-slip tape is used on the wedging material according til the FSO Sealand Guidelines.

When fixing with brackets, these must be fixed in the marked area.

Fixings in the jambs 150 mm from a corner and with a maximum spacing of 600 mm.

At the head and sill there can be a maximum of 600 mm between fixings.

For element widths under 600 mm fixings at the head and sill can be omitted

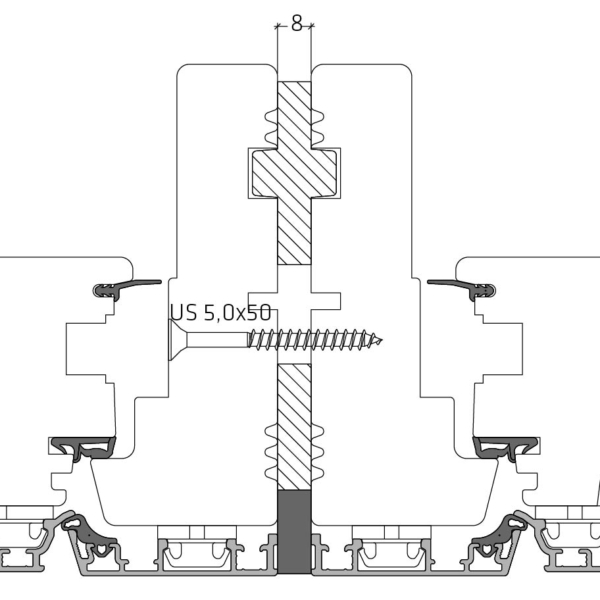

Coupled units have a mutual distance of 8 mm. In the rebate, the units are joined together with 5×60 mm wood screws. A silicon seal must be applied between the window units and the coupling strip. Exterior seal with silicon or Compriband.

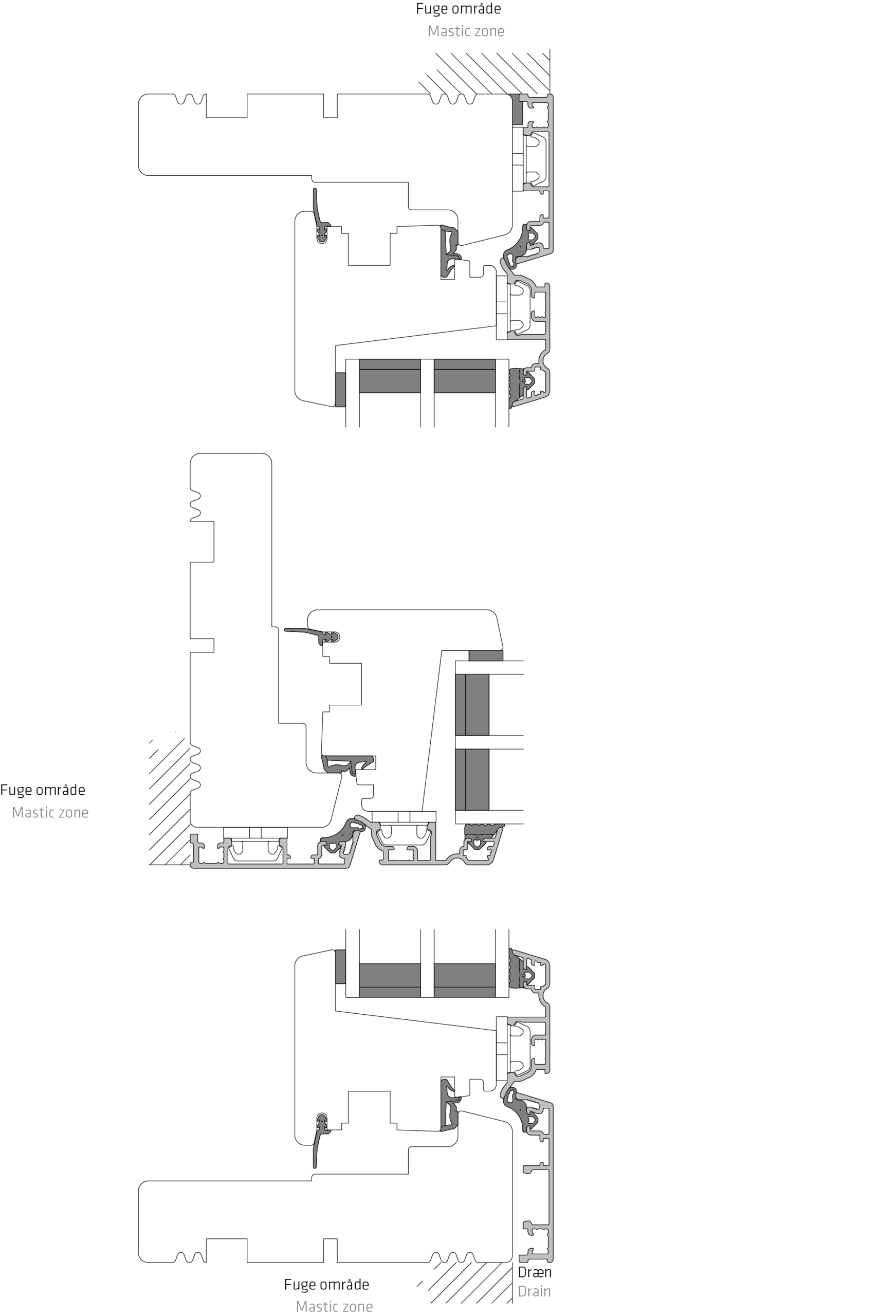

Adjoining elements should have a spacing of 8 mm. Join the elements together in the rebate using 5×50 mm wood screws. Apply mastic between the window units and spacer strip/cross tongue.

Seal outside using mastic or compriband.

At the jamb and head, the seal can be moved to the front of the aluminium frame.

Drainage happens at the sill between the wood and the aluminium. The seal under the sill must therefore be placed on the wood part, as shown on the drawing.

After installation all drilling dust is removed and locking points are lubricated. This will ensure long lasting trouble free operation.

Weather seals can be rubbed with a silicone stick.

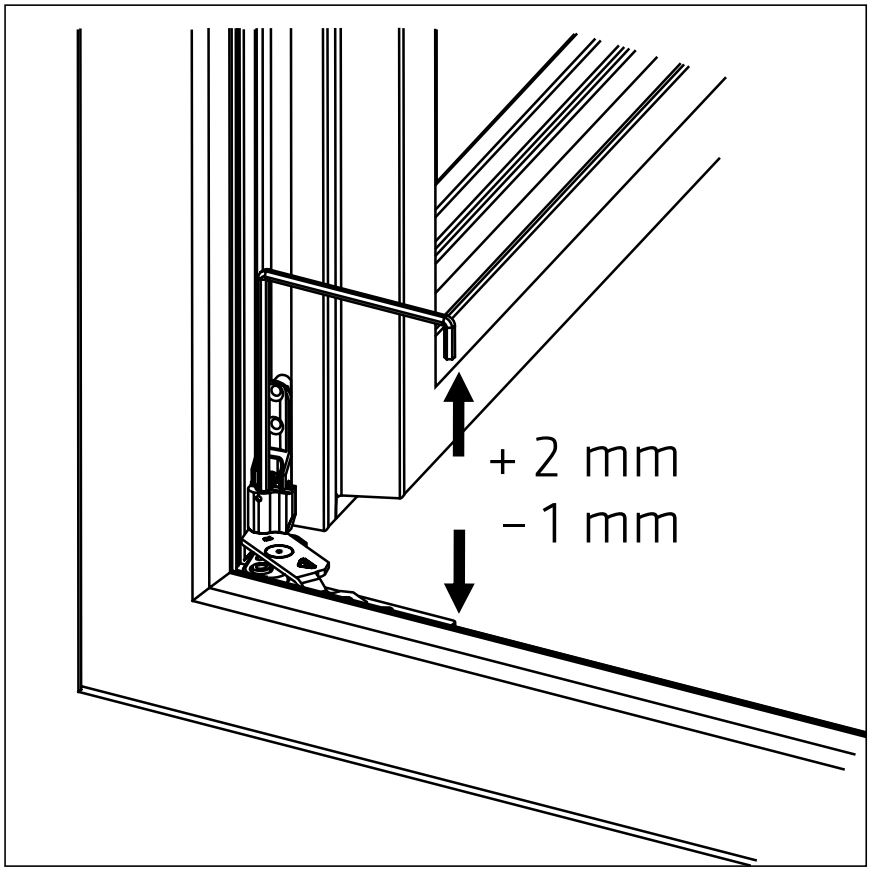

The sash rests on a pin at the bottom of the hinged side, allowing vertical adjustment.

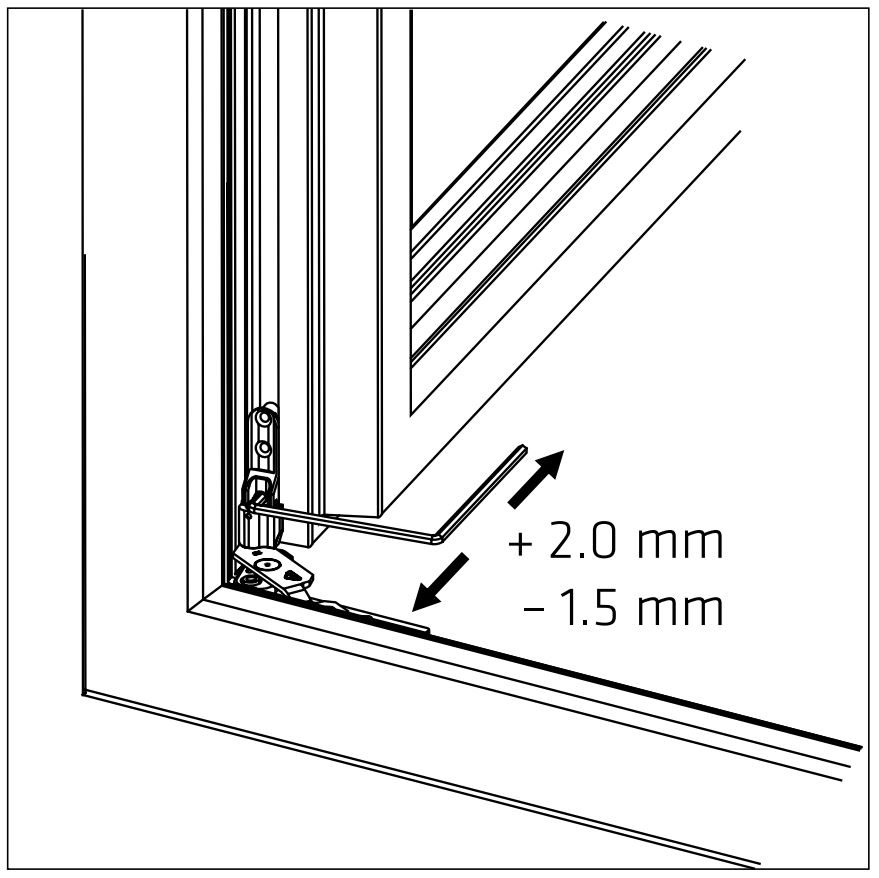

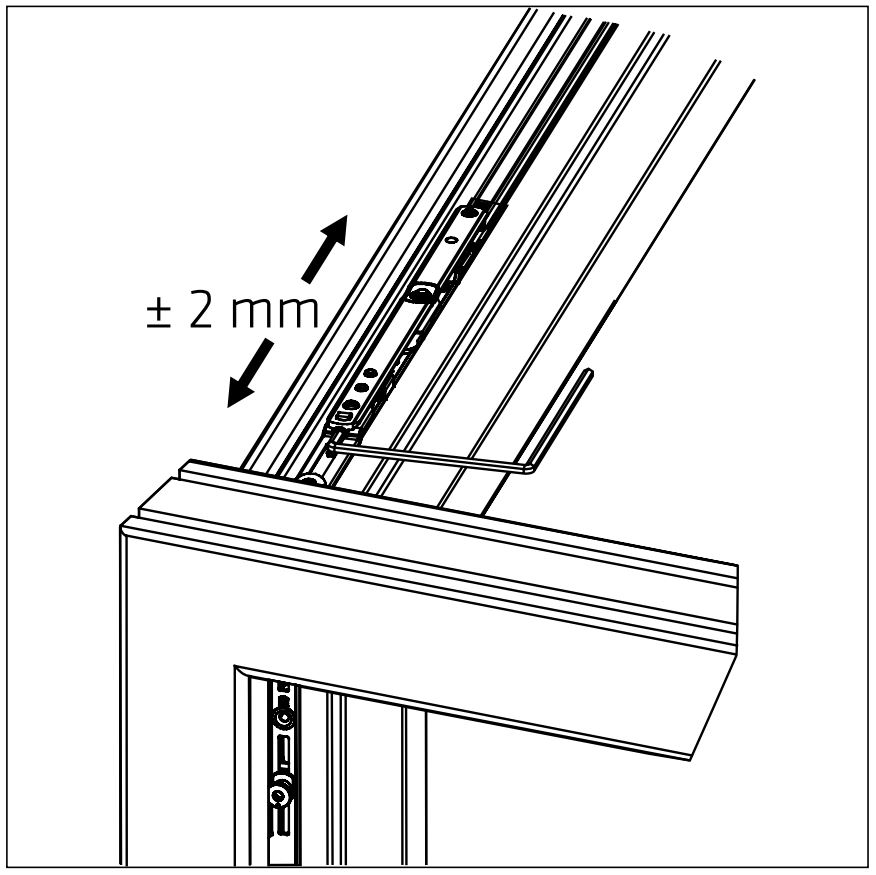

The sash rests on a pin at the bottom of the hinged side, allowing horizontal adjustment of the sash. The sash is guided by levers in the frame head, allowing horizontal adjustment of the sash.

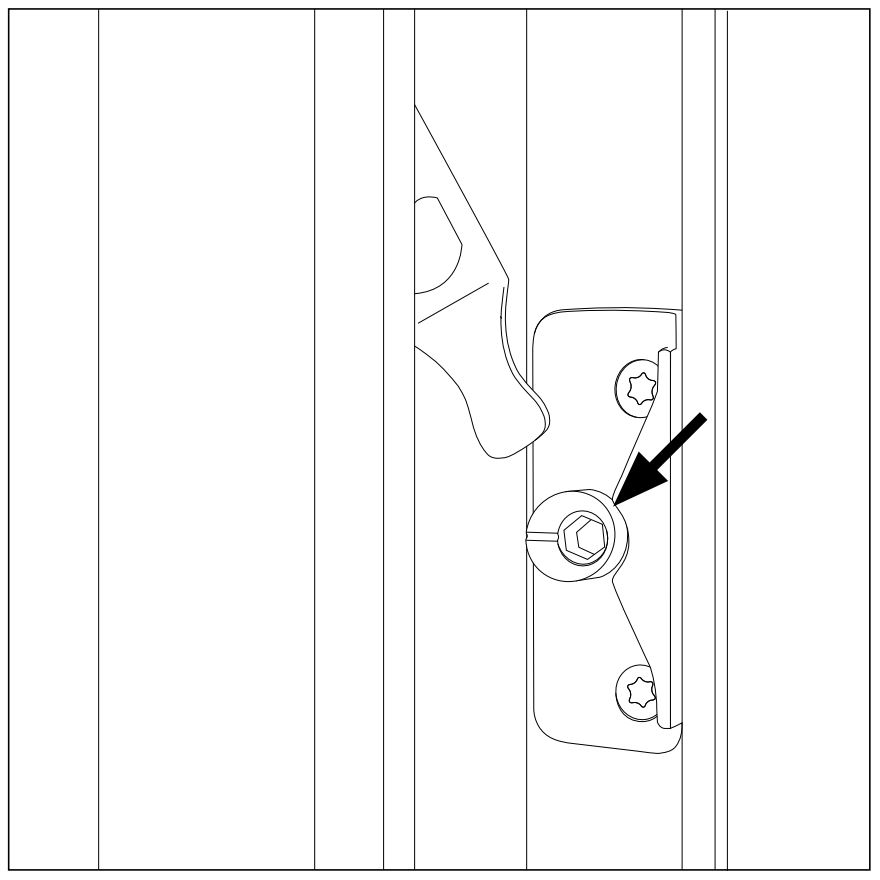

The mushroom bolts can be adjusted at any time to increase or decrease the tightness of the weather seals.

When closed, the sash is held up by a sash support. The sash support can be adjusted vertically to avoid the sash from dropping.

The outer aluminium sash and frame surfaces are affected by the surrounding environment such as city and industrial areas with high traffic intensity and air pollution and coastal areas with salty air which soil and affect the surface more than clean country air.

Cleaning should be done on a regular basis and at least twice a year, maybe in connection with window cleaning. Wash sash and frame surfaces in lukewarm water with a neutral cleaning fluid such as car shampoo and wipe surfaces and edges with a cloth.

The external aluminium profiles are as standard chrome free and surface treated with a polyester powder coating. This treatment offers a very strong and weather-resistant surface requiring only limited maintenance. In practice, this means cleaning it a couple of times a year with a soft brush or cloth and lukewarm water with a neutral cleaning fluid such as car shampoo.

Minor damage to the surface treatment will not affect the element’s durability since a natural oxide film quickly forms on exposed aluminium, preventing corrosion and white rust attacks.

However, for cosmetic reasons it may be desirable to repair such damage and Idealcombi’s Technical Department would be happy to provide advice and guidance. Call us on 01582 860 940.

The outer aluminium covering on our products in timber|aluminium can alternatively be supplied with anodic treatment. Once the aluprofiles have been chemically prepared and cleaned thoroughly, they undergo an electrolytic process. Direct current is applied to the profiles which become anodised, thus turning the surface metal into oxide. This process continues until the desired film thickness has been achieved.

An anodised surface treatment provides excellent corrosion resistance in most environments while keeping the surface very smooth and dirt repellent. On top of that it has the ability to preserve what we call a “new” appearance.

Anodised alu-profiles are almost maintenance-free provided that the surface is cleaned a couple of times a year with a soft brush or cloth and lukewarm water with a neutral cleaning fluid such as car shampoo.

When cleaning the wooden parts with lukewarm water and a neutral cleaning fluid, check for any damage or wear to the surface treatment.

All wood profiles from Idealcombi are quality optimised and finger jointed/ laminated ensuring elimination of at least 95% of all knots, star shakes and other defects. This gives the wood profiles greater stability and significantly reduces problems such as knot discoloration, yellow blotches and resin lumps in the surface treatment.

Please bear in mind that wood is a natural material and as such resin lumps may form underneath the paint and discoloration from the wood treatment may occur – even with the best surface treatment.

Small droplets of resin penetrating the paint can easily be removed with rubbing alcohol.

If small lumps of resin form underneath the paint, leave them for 2-3 years or until the resin has penetrated the surface treatment, then remove them with rubbing alcohol or, in more serious cases, scrape and sandpaper them away before applying new paint.

Yellow discoloration, which can normally be removed with rubbing alcohol, often occurs on light colour finishes.

The above mentioned problems are often more pronounced during hot summers (tropic climates) and may occur rapidly particularly on facades facing south.

For further information please see Danish Window Certification appendix 14, page 28 of the technical regulations which deal with “Expected outcome of industrially surface treated timber elements”.

Efficient preparation is key for the durability of the treatment.

Start by washing the area thoroughly with sugar soap or similar cleaning product. Loose paint is scraped off and any resin can be removed with white spirit.

Any exposed timber is primed with a clear wood primer.

When dry, sand down the primer on all flat surfaces and remove any sanding dust with a brush or cloth.

Finish of with two coats in the correct colour.

We recommend using a water based product similar to the one originally used.

We are happy to recommend nearest dealer of a suitable product.

• Always read the instructions on the chosen paint before commencing work.

• All surfaces and grooves must be dry and free from dirt and dust before commencing work.

• Neither weather strips nor moving parts in hinges and espags can be painted. Please note that seals are loosely fitted, and can be removed before painting, and refitted when the paint is dry.

• DVC’s guarantee label must not be painted.

• Masking tape is recommended for best finis along edges.

• Always use a good paint brush in a suitable width.

• Always have a cloth and plastic bag at hand. Use the cloth to dry off incorrect strokes and drips from the brush. Use the plastic bag to wrap around your brush if your work is interrupted for a short period of time.

• Remember that hinged sashes must not be closed before the paint is completely dry.

It is important to lubricate and maintain all ironmongery to ensure easy operation and function of Idealcombi’s windows and doors, this is also a requirement to maintain the product guarantee.

For lubrication, use an acid-free lubricant followed by an acid-free spray grease. Lubrication can be made with an oil can, a syringe or a spray can with a thin pipe. For further advice on lubrication, please call Idealcombi’s Service Department on tel. 01582 860 940.

Lubrication and maintenance frequency depend on the use and the effect weather conditions, pollution, etc. have on the ironmongery.

We know from experience that ironmongery used in for instance city and industrial areas, areas with high traffic intensity and coastal areas with salty air should be lubricated and maintained more often than ironmongery in a less harsh environment.

Generally, all moveable parts on hinges and closing/locking ironmongery should be lubricated as required, however, at least once a year.

Hinges should be lubricated in all joints during repeated activation, so that the lubricant reaches the movable arms.

The joints should be lubricated on the outside and in the crack between the arms. Use an easily penetrating acid-free oil followed by a long-lasting acid-free grease in spray form.

Hinges should be lubricated in all joints during repeated activation, so that the lubricant reaches the movable arms.

The joints should be lubricated on the outside and in the crack between the arms.

Sliding surfaces, hinge sliders and sliding blocks should be maintained in a clean state to facilitate sliding.

IMPORTENT!

The sliding surfaces in the sliding rails are lubricated with Berner PTFE oil or equivalent along the entire length the rails.

Should be lubricated in all moving parts, lock boxes and by bolts and keeps while activating the mechanism continuously, to ensure the lubricant penetrates in between all moving parts.

Should not normally be lubricated. The tracks should always be kept clean.

During the annual maintenance service, cleaning and lubricating ironmongery, weatherstrips and glazing gaskets should be inspected.

Our weatherstrips are made from EPDM rubbers and several of them in a combination with a solid foot and a soft cellular sealing surface.

The weatherstrips do not require any special maintenance but should be kept clean and free of dirt. This is done by wiping them off once a year with lukewarm water and a neutral cleaning fluid using a cloth. We recommend brushing the weatherstrips with a silicone stick to minimize friction during operation.

Also check that the weather strips are positioned and secured correctly and that they have maintained their sealing function.

All weatherstrips are loosely fitted in a perimeter groove making them easy to remove and install on most element types if they are damaged and need replacement – or in connection with surface treatment maintenance.

Never paint weatherstrips or brush them with wood preservatives/oils.

Glazing gaskets are made of EPDM/cell rubbers and doe not require any special maintenance but should be kept clean and free of dirt. This is done by wiping them off once a year with lukewarm water and a neutral cleaning fluid using a cloth.