Frame I Turn/Tilt Window

Use

Turn-tilt windows are often used in multi-storey buildings or where external sun protection is installed. Frame I / Nation I (inward-opening) and Frame IC / Nation IC (outward-opening) have the same exterior frame height and can therefore be placed in the same facade, without there being much visual difference.

The turning function is used primarily in connection with cleaning the outside of the window, while the tilting function is used for daily ventilation and venting. The turning function can also meet all the building regulations' requirements for rescue openings.

Function

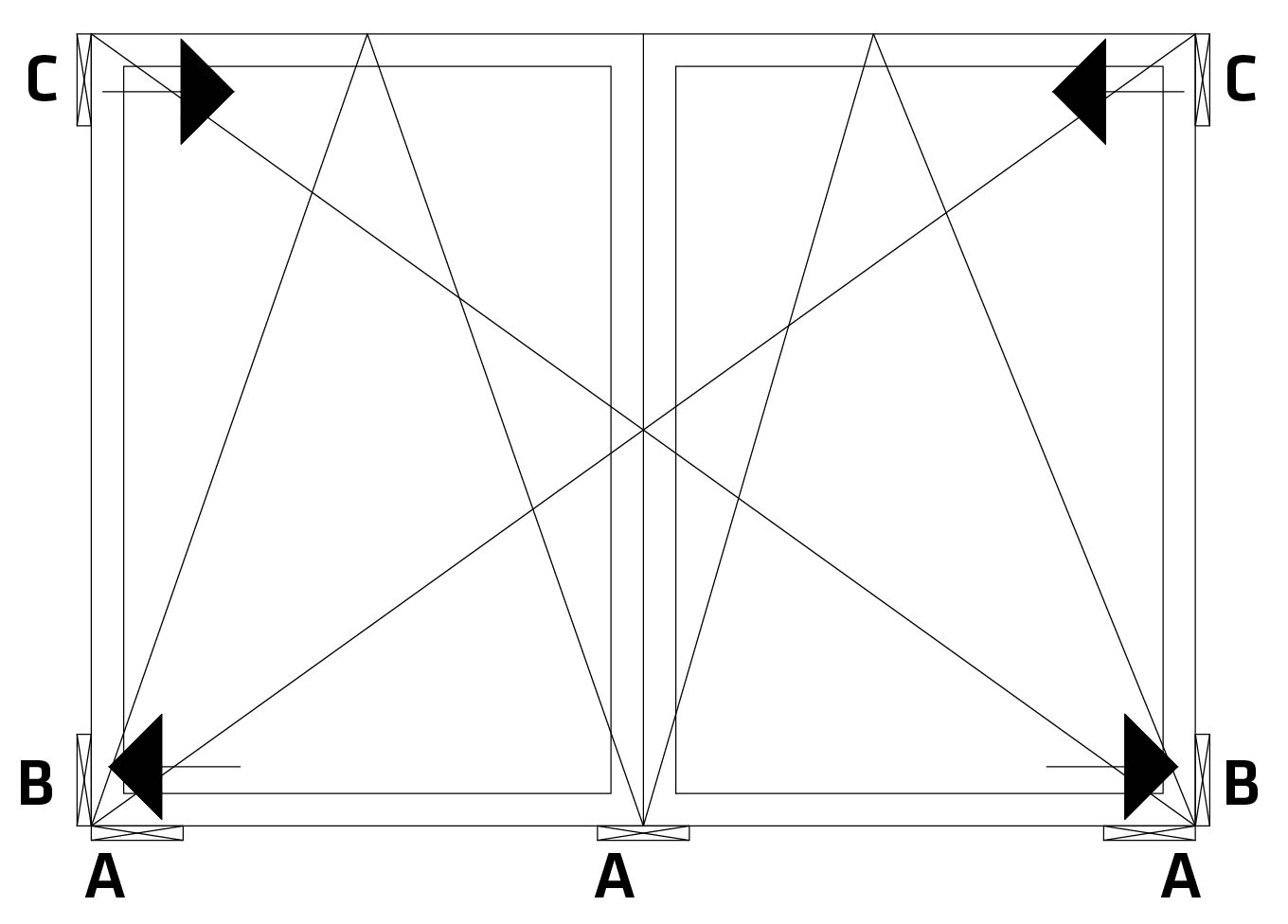

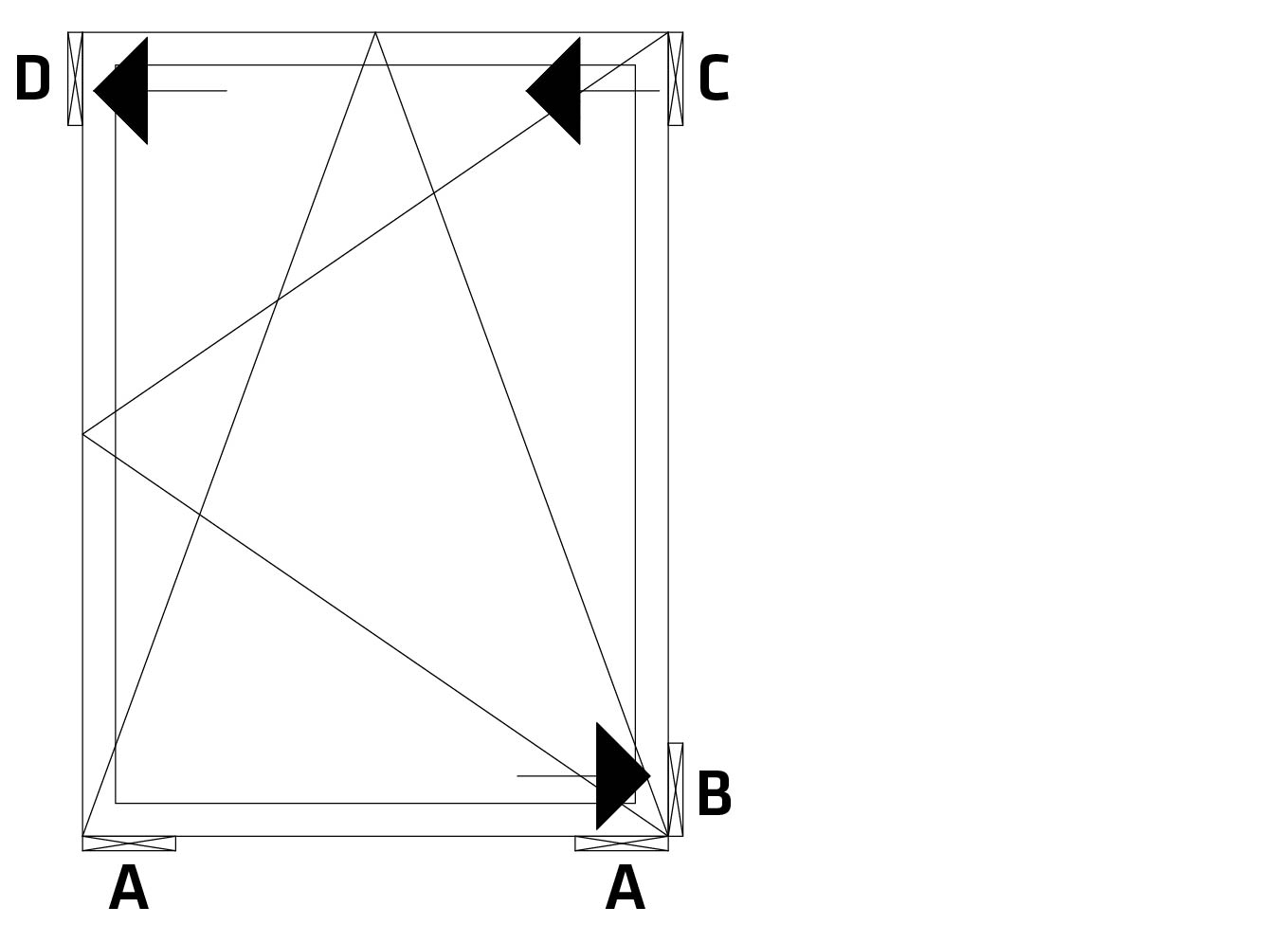

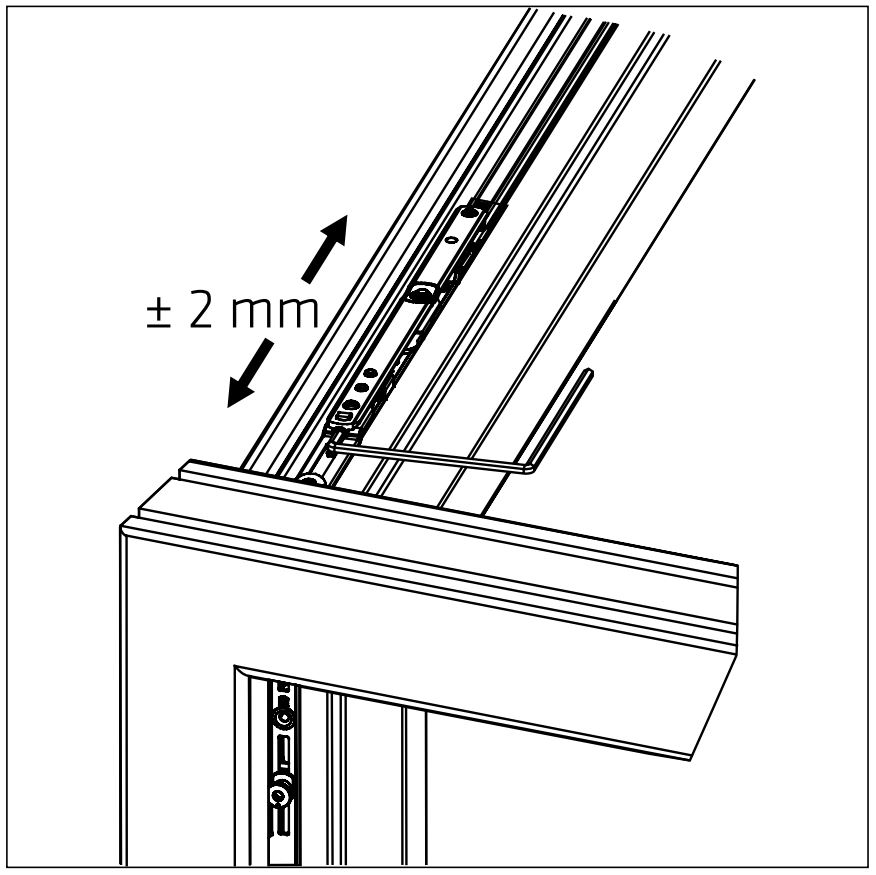

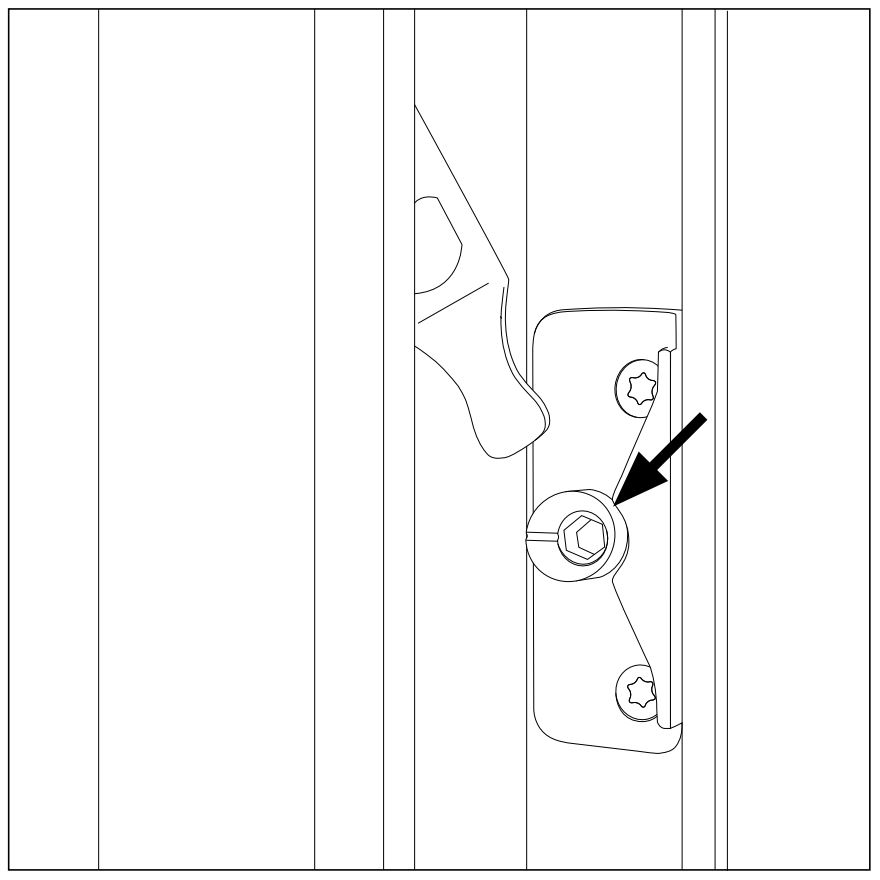

The turn-tilt window is an inward-opening window with both side- and bottom-hung function. Both opening functions are controlled by the fitting lever in the side frame. In the closed position, the handle faces vertically downwards and the turning function is triggered by turning the handle 90° to the horizontal position. The tilt function is triggered by turning the handle 180° in an upright vertical position. With tilt function, the upper edge of the frame moves approx. 14 cm inwards and gives a free opening of approx. 4 cm.

The turn-tilt window can, as an option, be supplied with a handle operated brake. The brake can, in the turning function, hold the frame in any position above 18° opening.

- Product information:

- Uw: 0,82 (Medi g) | 0,85 (High g)

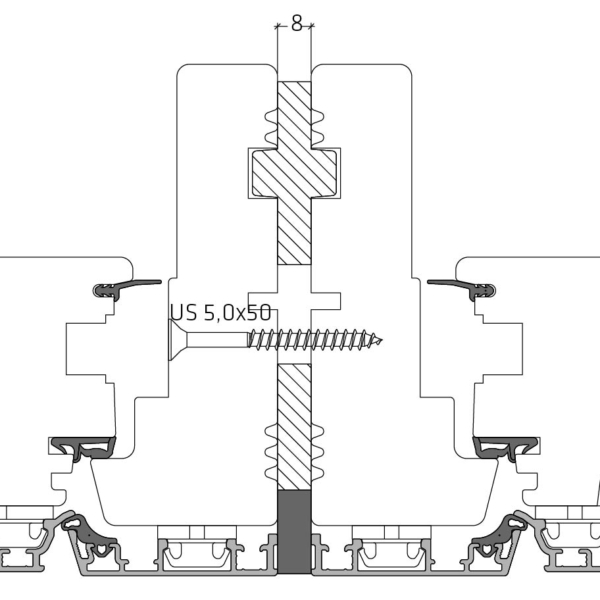

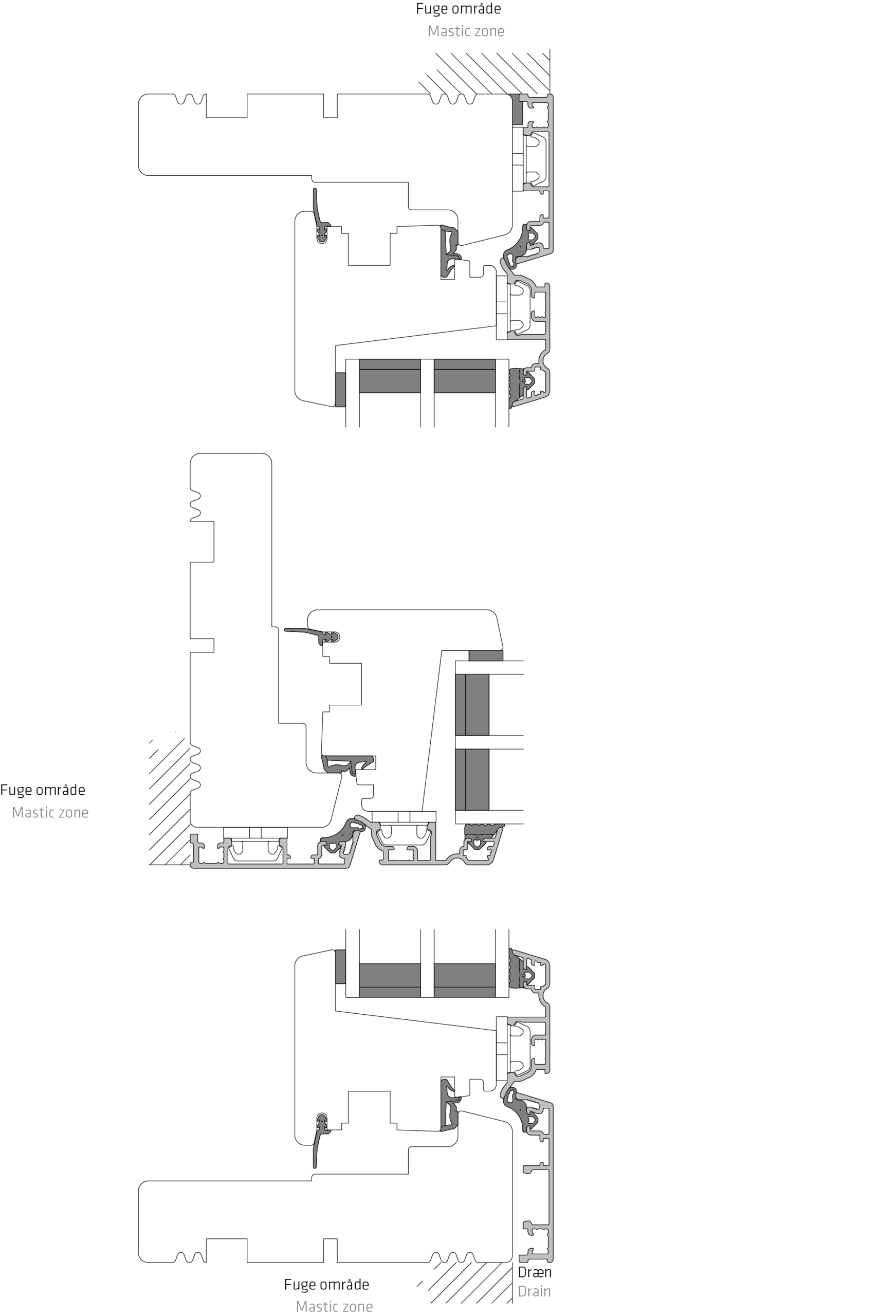

- Glass dimensions: Triple glazing (48 mm): 4-18-4-18-4

- Styling bar: 22/23 mm og 42 mm

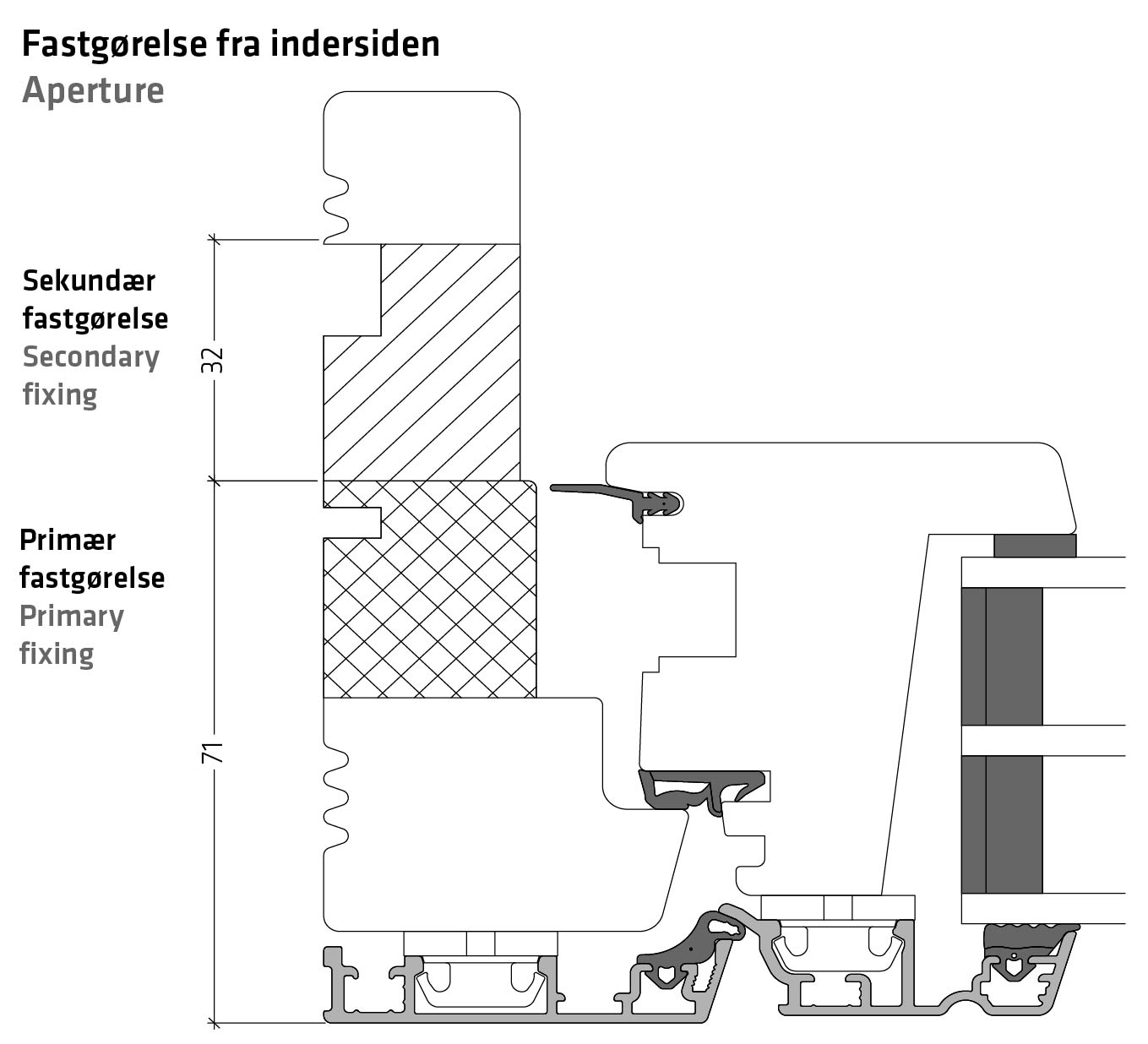

- Frame dimensions: 50 x 122 / 149 mm